Boiler room

- 2 Babcock & Wilcox boilers (of 300 H.P.) with steam gauges and water columns and with Metropolitan injector and Worthington feed pump.

- 1 Other feed pump.

- 1 Hand blacksmith and forge.

Adjoining boiler room:

- 7 Toiletes.

- 1 Urinal.

- 6 Wash basins.

Babcock & Wilcox boiler

http://boilerbasics.blogspot.com.es/2011/08/babcock-and-wilcox-boiler.html

Characteristic:

- Horizontal Boiler

- Muli tube Boiler

- Water tube Boiler

- Straight tube Boiler

- Externally Boiler

- Multi tube Boiler

- Natural draft Boiler

- Natural circulation Boiler

- Coal fired Boiler

- Stationary Boiler

- Low & Medium pressure Boiler

Construction: Babcock and Wilcox boiler with longitudinal drum. It consists of a drum connected to a series of front end and rear end header by short riser tubes. To these headers are connected a series of inclined water tubes of solid drawn mild steel. The angle of inclination of the water tubes to the horizontal is about 15° or more.

Working: The fire door the fuel is supplied to grate where it is burnt. The hot gases are forced to move upwards between the tubes by baffle plates provided. The water from the drum flows through the inclined tubes via down take header and goes back into the shell in the form of water and steam via uptake header. The steam gets collected in the steam space of the drum. The steam then enters through the antipriming pipe and flows in the superheater tubes where it is further heated and is finally taken out through the main stop valve and supplied to the Steam turbine or Steam engine when needed.

The pressure of steam in case of cross drum boiler may be as high as 100 bar and steaming capacity upto 27000 kg/h.At the lowest point of the boiler is provided a mud collector to remove the mud particles through a blow-dawn-cock.

Advantages:

- It uses both solid as well as liquid fuel for burning.

- The drought losses as compared to other boiler in minimum.

- As compared to other boiler the evaporation capacity is high.

- The circulation of water is natural.

- The defective tubes can be replaced easily.

- It is used in power stations for generation large quantity of steam.

http://www.studyvilla.com/boilers.aspx

The tubes can be cleaned or replaced through hand-holes that are place ahead of each tube. The collecting boxes, on the boilers front side, are in the down-end connected to a mud disposal box with a blow down valve. The upper end of the collecting boxes by means of elbowed pipes connected to the lying steam drum. The collecting boxes at the water tubes rear side are closed at both ends. From the upper ends are tubes connected to the steam drum above the water level. At normal conditions the water level will be little below the mid-point of the steam drum.

Boiler Fittings and Accessories:

- Safety valve: It is used to relieve pressure and prevent possible explosion of a boiler.

- Water level indicators: They show the operator the level of fluid in the boiler, also known as a sight glass, water gauge or water column is provided.

- Bottom blowdown valves: They provide a means for removing solid particulates that condense and lay on the bottom of a boiler. As the name implies, this valve is usually located directly on the bottom of the boiler, and is occasionally opened to use the pressure in the boiler to push these particulates out.

- Continuous blowdown valve: This allows a small quantity of water to escape continuously. Its purpose is to prevent the water in the boiler becoming saturated with dissolved salts. Saturation would lead to foaming and cause water droplets to be carried over with the steam - a condition known as priming.

- Flash Tank: High pressure blowdown enters this vessel where the steam can 'flash' safely and be used in a low-pressure system or be vented to atmosphere while the ambient pressure blowdown flows to drain.

- Automatic Blowdown/Continuous Heat Recovery System: This system allows the boiler to blowdown only when makeup water is flowing to the boiler, thereby transferring the maximum amount of heat possible from the blowdown to the makeup water. No flash tank is generally needed as the blowdown discharged is close to the temperature of the makeup water.

- Hand holes: They are steel plates installed in openings in "header" to allow for inspections & installation of tubes and inspection of internal surfaces.

- Steam drum internals, A series of screen, scrubber & cans (cyclone separators).

- Low- water cutoff: It is a mechanical means (usually a float switch) that is used to turn off the burner or shut off fuel to the boiler to prevent it from running once the water goes below a certain point. If a boiler is "dry-fired" (burned without water in it) it can cause rupture or catastrophic failure.

- Surface blowdown line: It provides a means for removing foam or other lightweight non-condensible substances that tend to float on top of the water inside the boiler.

- Circulating pump: It is designed to circulate water back to the boiler after it has expelled some of its heat.

- Feedwater check valve or clack valve: A non-return stop valve in the feedwater line. This may be fitted to the side of the boiler, just below the water level, or to the top of the boiler.

- Top feed: A check valve (clack valve) in the feedwater line, mounted on top of the boiler. It is intended to reduce the nuisance of limescale. It does not prevent limescale formation but causes the limescale to be precipitated in a powdery form which is easily washed out of the boiler.

- Desuperheater tubes or bundles: A series of tubes or bundles of tubes in the water drum or the steam drum designed to cool superheated steam. Thus is to supply auxiliary equipment that doesn't need, or may be damaged by, dry steam.

- Chemical injection line: A connection to add chemicals for controlling feedwater pH.

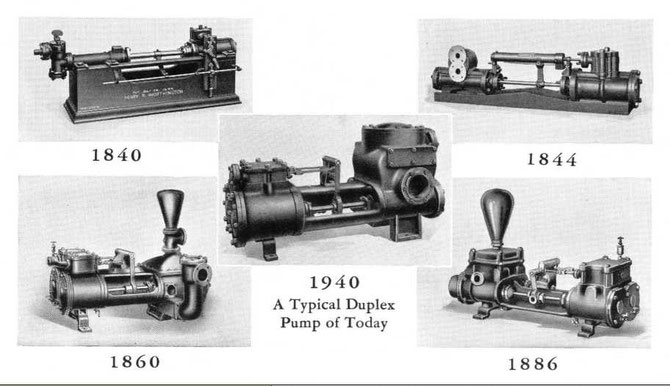

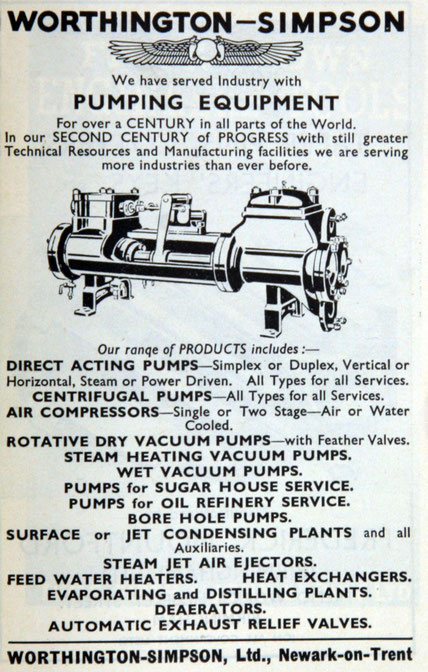

Worthington feed pump

http://en.wikipedia.org/wiki/Boiler_feedwater_pump

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type.

Steam locomotives and the steam engines used on ships and stationary applications such as power plants also require feedwater pumps. In this situation, though, the pump was often powered using a small steam engine that ran using the steam produced by the boiler. A means had to be provided, of course, to put the initial charge of water into the boiler (before steam power was available to operate the steam-powered feedwater pump). The pump was often a positive displacement pump that had steam valves and cylinders at one end and feedwater cylinders at the other end; no crankshaft was required.

A duplex steam pump has two sets of steam and water cylinders. They are not physically connected but the steam valves on the first pump are operated by the movement of the second pump's piston rod, and vice-versa. The result is that there are no "dead spots" and the pump is always self-starting.

Metropolitan injector

http://en.wikipedia.org/wiki/Injector

Steam injector, eductor-jet pump or thermocompressor is a type of pump that uses the Venturi effect of a converging-diverging nozzle to convert the pressure energy of a motive fluid to velocity energy which creates a low pressure zone that draws in and entrains a suction fluid. After passing through the throat of the injector, the mixed fluid expands and the velocity is reduced which results in recompressing the mixed fluids by converting velocity energy back into pressure energy. The motive fluid may be a liquid, steam or any other gas. The entrained suction fluid may be a gas, a liquid, a slurry, or a dust-laden gas stream.

http://www.rypn.org/forums/viewtopic.php?f=2&t=23365

Metropolitan 6-1/2O or 6-1/2G Double-Tube Injectors or parts.

The 6-1/2O, "1898" model, and 6-1/2G are lever style injectors with a capacity of 350 gallons at 80 Lbs at a 2 foot lift. Fittings are 3/4 inch.

http://www.squidoo.com/steam-injection

The steam is turned on by a screw spindle valve. It has three fixed nozzle tubes, A, B, F. A disc relief-check valve, C, and a wing check.

Hand blacksmith & forge

Blacksmith Scene (also known as Blacksmith Scene #1 and Blacksmithing Scene) is an 1893 American short black-and-white silent film directed by William K.L. Dickson, the Scottish-French inventor who, while under the employ of Thomas Edison, developed the first fully-functional motion picture camera.

Other links to check:

- http://www.gutenberg.org/files/10998/10998-h/10998-h.htm

- http://www.hnsa.org/doc/destroyer/steam/sec05.htm

- http://chestofbooks.com/reference/American-Cyclopaedia-11/Steam-Boiler.html#.UzR8SoWHMT5

- http://en.wikipedia.org/wiki/Water-tube_boiler

- http://www.studyvilla.com/boilers.aspx

- http://www.coolspringpowermuseum.org/Publications/Flywheel/Flywheel_201402.htm

- http://www.smokstak.com/forum/showthread.php?t=99279

- http://www.gracesguide.co.uk/Worthington_Pumping_Engine_Co

- http://www.isses.org.uk/gallery2/main.php?g2_itemId=5129

Inventions & Experiments

of Nikola Tesla

Inventions & Experiments

of Nikola Tesla

Write a comment